There are various types of ultrasonic welders. These are the basic thermoplasticity of the materials that they can be welded, as well as metal ultrasonic welding. These ultrasonic welds are also classified on the basis of the work of the instrument of the ultrasonic welder. This blog is all about the discussion of various types of ultrasonic welders. So, without delay, let’s start this interesting topic.

Types of Ultrasound Welding

Ultrasonic welding machine has many types. To simply and understand their types, we have made two basic classifications to classify and divide them into two classifications to make its types understand more.

On the basis of the Nature of the material being welded

The ultrasonic welding machines are of two types if we classify them on the basis of whether they can weld a thermoplastic material or thin metal.

1. Thermoplastic Ultrasonic welding

As is clear from the name, this type of ultrasonic welding works only with heat-sensitive plastic. Therefore, it is suitable for bonding and welding plastics. Therefore, it is used to combine and weld these plastic materials in the shoe, automotive, and other plastic industries.

Working

This is because its horn, which is installed with a vibrator, simply works as if applying pressure on two plastics. High frequencies are then used to create high vibrational energy that heats plastic. The plastic, after heating, is melted, after which it can be cooled to weld the plastic normally.

" alt="" class="wp-image-2607" style="width:305px;height:auto"/>

" alt="" class="wp-image-2607" style="width:305px;height:auto"/>Application

It is used in:

- Automotive

- Aeroapce

- Shoes

- Jackets

- Other plastic industries

2. Ultrasonic metal welding

Ultrasonic metal welding is similar to plastic welding, but only in some parts and work mechanisms are different. This type is for thin metal only. As a low heated, it can only be used for a thin metal of several millimeters. When the thickness of the metal is several millimeters to several tens of millimeters, it will not work.

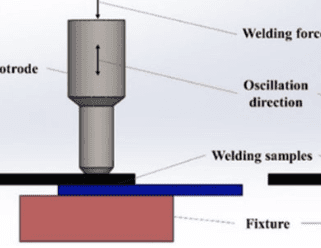

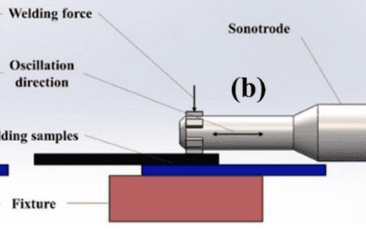

Working

A sonotrode (horn) for generating high-frequency vibration is mounted, and pressure is applied to the thin metal. Pressure and Force High at a Given Point By adding, you can generate heat, increase the frictional force, and metallize metal. The two metals are cooled at the welding point to form a welded part.

" alt="" class="wp-image-2608" style="aspect-ratio:1;width:266px;height:auto"/>

" alt="" class="wp-image-2608" style="aspect-ratio:1;width:266px;height:auto"/>Application

It is used in:

- Thin meta industry

- Aerospace

- Building metals aluminium working

On basic of working of Sonar Horn

The ultrasnoc welding are of two main types on the basic of direction of working of Sonar horn or sonotorde:

Linear Horn Ultrasonic Welder

In this type, the horn or sonotrode moves in a straight direction to perform this task. Two plastic or thin metals are sandwiched between them, and pressure and force are applied to the metal joints where welding is required, and then the joints are cooled for some time.

Circular Horn ultrasonic welding machines

In this case, the horn moves in a circular direction, and the metal or plastic comes into contact with it, melting the metal or plastic at two points, and then cooling, finally joining. This process is more difficult than linear. It is done by experts and cannot be done by beginners.

Conclusion

This time, we talked about the types of ultrasonic welders. Ultrasonic welding is becoming more common these days because it can perform multiple tasks, and there is no noise. Modern ultrasonic welders are very smart; by using batteries, they also work.