Jewelry has gained special status in many cultures around the world, which began with the evolution of civilization. Both men and women wear jewelry, but women use it for a better look. Jewelry, which is part of culture, is often worn by women at weddings and other ceremonies.

Men wear gold watches and rings. But women want to wear bracelets, rings and many other jewelry items made from gold and silver. As new fashion trends related to jewelry are on the market, so the new tecnhinques of making jewelry are also used today. Now permanent jewelry has become very trendy and popular.

Therefore, the technology of making such new jewelry is also used. The new fashion is about welding permanent jewelry. This welding is different from other types of welds, such as stick and MIG welds, so more care and experience is required. In this blog, I will answer the question of how to weld permanent jewelry. Let’s start this article without wasting time.

Basic Principle of Permanent Jewelry

The basic thing that must be taken into account when performing welding is the choice of chain type. After the chain is wrapped around the wrist, the ends of the chain are adjusted to fit the wrist so that they can be easily removed when needed in the future. At the point where the chain fits, the technician cuts it to be welded by the use of a welder of jewelry using preventive measures that protect the hands of those who use this permanent bracelet.

This was a general overview of permanent welds. Now we will talk about welding jewelry in simple steps.

9 Simple Steps to Weld Jewelry Permanently

1. Selection of Chain

The first step is the selection of the chain by the user who wants to get a permanent bracelet around his / her wrist. He/she chooses the style and color of the chain in which they want to get permanent welds.

2. Measuring the Chain

When a user selects a chain, the artist or jeweler puts the chain on the wrist, adjusts it so as to fit in the hand, and can easily remove it as needed. Jewelers or technicians mark the points to cut so that they can be welded to both ends of the chain.

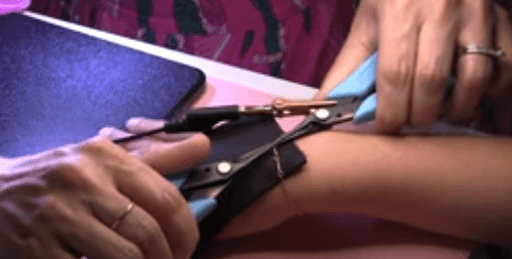

3. Cutting of the chain

After marking the cut point on one side of the chain, the artist cuts the chain using a cutter or a pliers.

" alt="" class="wp-image-2776" style="width:780px;height:auto"/>

" alt="" class="wp-image-2776" style="width:780px;height:auto"/>4. Use of a Jump ring

Both ends of the cut chain are held around the wrist of the user, and both ends of the chain are fixed without being welded by using a jump ring.

5. Connecting the jumper ring with the grounded electrode of the jewelry welder

Next, connect the jump ring to the negative or earth electrode of the jewelry welder. There are many types of jewelry welders. The principle of operation is the same regardless of the type.

" alt="" class="wp-image-2777" style="width:780px;height:auto"/>

" alt="" class="wp-image-2777" style="width:780px;height:auto"/>6. Covering the Wrist for protection

The heat from the welding arc, which can damage the skin, should be avoided by placing protective leather between the chain and the skin so that the heat from the welding arc does not damage the skin.

7. Welding the chain

After checking the protective measures and joining both ends of the chain using a jump ring and pliers, the welder brings the positive electrode closer to both ends. A complete electrical circuit generates an electric arc, this arc immediately melts them and welds.

8. Cleaning of the weld

After the jewelry chain is welded, the weld is shielded using a stable gas such as helium or argon and cleaned so that it does not rust easily.

9. Polishing of the weld

If the welding is noticeable, the appearance of the chain does not remain good. Therefore, it is necessary to polish the welded part and improve the appearance of the chain.

By following the above steps, you can weld permanent jewelry within minutes.

Precautions during the welding

Since it is directly contact with the skin, it is necessary to use protective equipment such as leather that protects the skin from the heat of the welding machine. he person is recommended to wear the auto-darkening lens during the welding, and he/she is asked to look somewhere else.

Durability of the permanent jewelry weld

Permanent jewelry welding is suitable to ensure long-lasting and durable jewelry. It’s not easy to break, and there’s no tension. You can not easily lose it. Some of the key factors that determine the long-lasting fate of it are mentioned here:

Types of jewelry items

If you have welded the jewelry items that are used in feet as compared to bracelets, you use for your wrist, then no doubt the weld of foot jewelry will break early as compared to others. Similarly,y if you get permanent jewelry welded for neck jewelry, it will last as it does not face more bolts.

Types of metal

The weld quality of silver is different from compared of gold. Similarly the weld to gold is different from bronze or any other metal. The weld will long faste depends whether it rust easiy or not. As the gold is not rusted easily so its weld will last longer than the silver gold.

Advantages of Permanent Jewelry

There are many benefits that can be obtained by applying permanent welding to jewelry.

- Bracelets and jewelry are not easily lost, as they cannot be easily opened.

- It can be removed from part of the body when necessary.

- The weld is long-lasting.

- It prevents you from the again and again using connectors and jump wires.

Cost of getting permanent jewelry

You can get permanent jewelry near you where a jewelry shop is present. You can go there and ask them to get a permanent weld. The price of permanent welds is very high compared to other types of welds. Its usual price range is $ 80-120 for welding a single bracelet.

Do we need to clean the permanent bracelets consistently?

Yes, permanently welded jewelry needs to be repeatedly cleaned with special chemicals that maintain its appearance and charm.

Can we remove permanent jewelry easily when required?

Yes, you can remove it easily when required, as it is welded in such a way that you can remove it later when you need.

Conclusion

This was all about permanent welding of jewelry. It is better because it will last longer and be more durable. You can not easily lose it. You need to use safety measures before giving permanent welding.